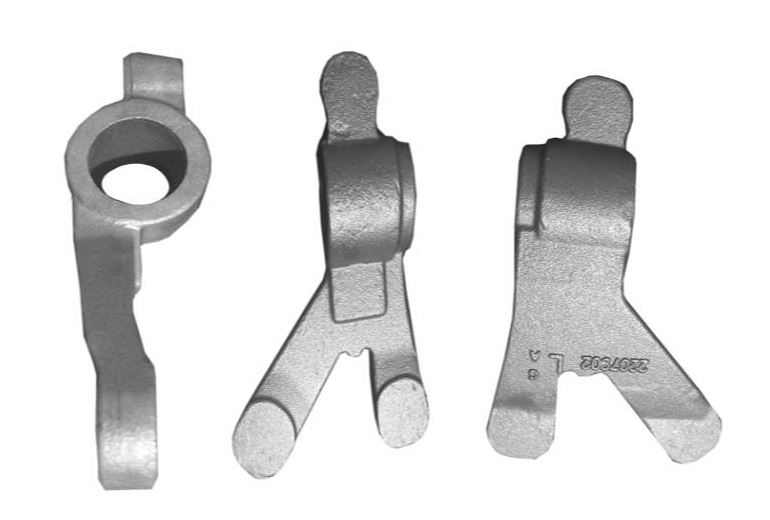

FORGING COMPONENTS

Forging Types (Hot & Warm)

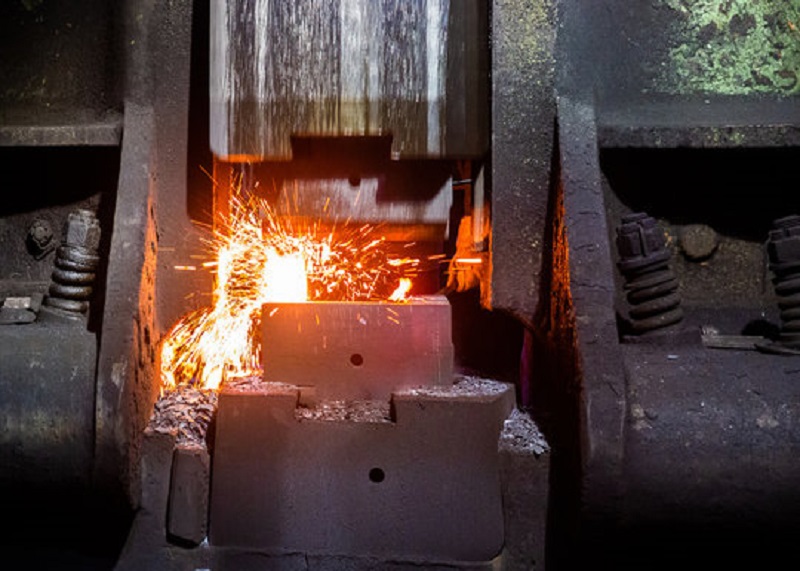

- Forging through hammer is the modern-day version of the pre-industrial blacksmiths work, with a hammer and chisel.

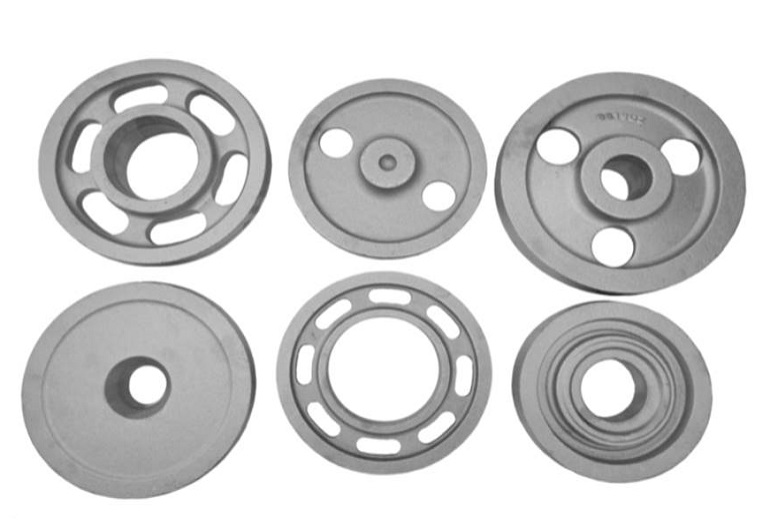

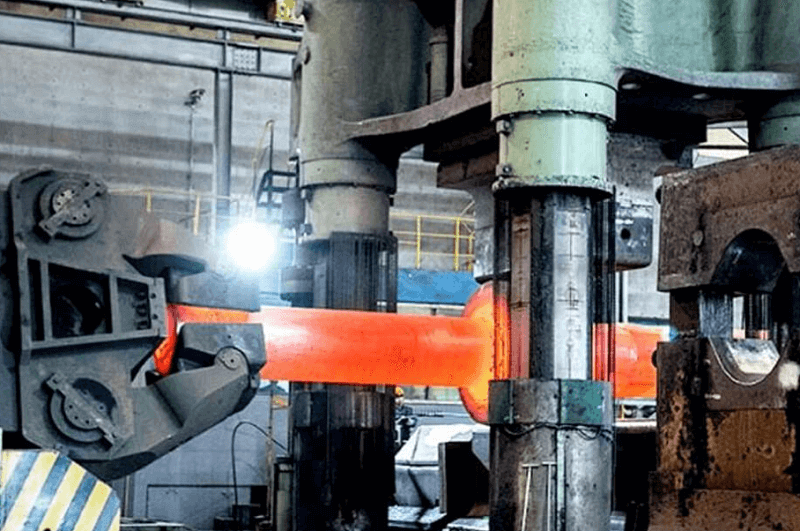

Forging through Press

- Forging through Press Press forging may be defined as the process of shaping a metal that is placed between two dies by applying mechanical pressure or hydraulic pressure.

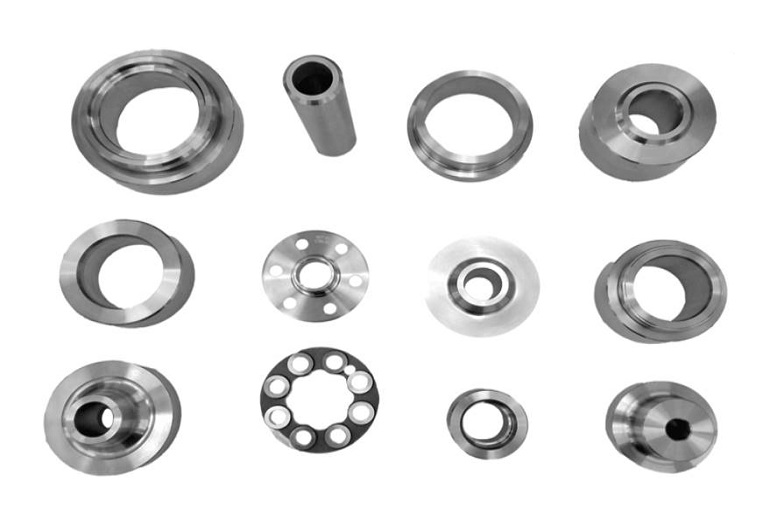

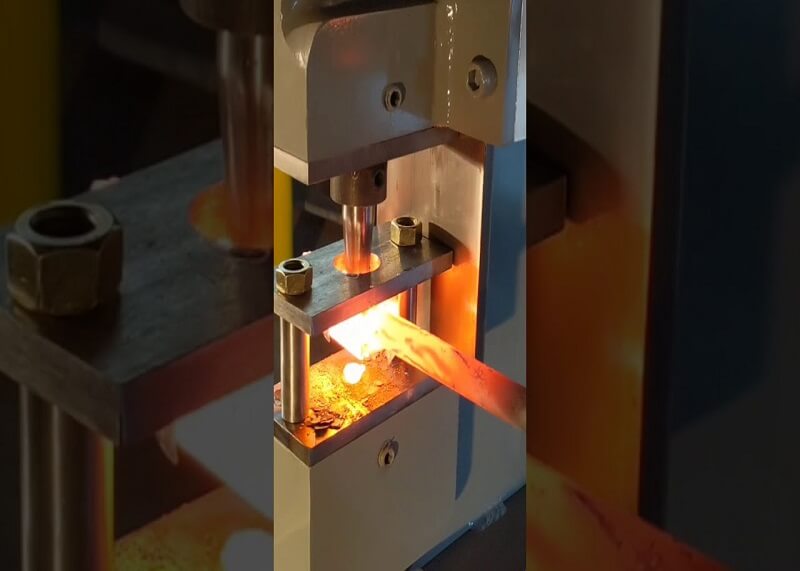

Forging through RING ROLLING

Ring Rolling Forging, also known as roll forming, is a forging technique that involves shaping a metal object with opposing rollers. Although roll forging uses rolls to achieve material deformation, it is a discrete process, not a continuous one, analogous to metal forging rather than metal rolling.

Ring forging is frequently done in a heated environment. The roll’s grooves are carefully designed to forge the part to the desired dimensions.

The forging geometry of the rings used to forge metal items is only visible on a small fraction of the diameter of the ring. Only a portion of a full ring revolution is required to forge the workpiece.

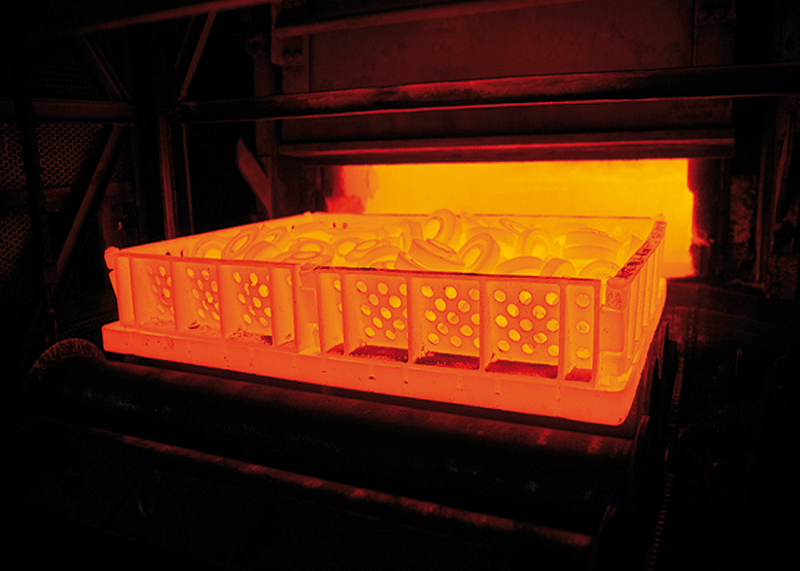

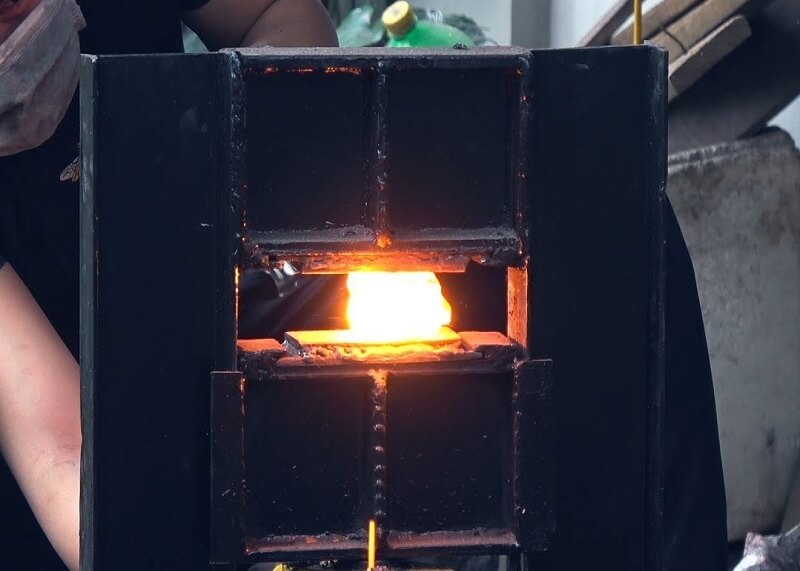

Heat Treatment

Heat treating is used to alter and improve the physical properties of a given material using a heat treat furnace. Typical heat treatment techniques applied to steel forgings include annealing, normalizing, quenching, and tempering. Precipitation hardening applies to superalloys, titanium and some PH stainless steels.

Heat Treatment is one of the main value added services CFS Forge offers for steel forgings. Heat treatment is a post treatment method that aims to change the mechanical properties of produdcts for better working performance. All the steel forgings can be heat treated after forging.

The heat treatment after closed die forging plays an important role in developing the desired properties such as the relieving of internal stresses, the refinement of grain structure, and the attainment of improved mechanical and physical properties. For machinability, CFS Forge supplies forgings in the annealed, normalized, normalized and tempered, process annealed, spheroidized or full annealed condition. The steel forgings may then be quenched and tempered to achieve the final desired properties. Below we will introduce some of the common heat treatment methods after forging available at CFS Forge.